The industrial revolution changed the world, utilizing ingenious inventions created using first-class brainpower- long before computers or other advanced technologies existed. To revisit that historic period, and understand its local influences, distant travel isn’t required; an amazing legacy of industry innovation is celebrated at Waynesboro’s Industrial Museum.

Originally founded as part of Waynesboro’s sesquicentennial in 1997, and later chartered in 2000, the Waynesboro Area Industrial Heritage Trust (WAIHT) provides thoughtful insight into the legacy of past industry titans and their companies.

WAIHT’s Industrial Museum is curated and managed by dedicated volunteers, some who were leaders in their respective industries. The museum houses a significant collection of artifacts, photographs, and documents. The WAIHT group also conducts research, hosts exhibitions, and sponsors educational programs to enhance local knowledge about industry that once prospered, and still thrives today, in the Waynesboro area.

During an historic era, four men, with three different last names, catapulted Waynesboro toward achieving a worldwide reputation for industry excellence. George Frick, Peter Geiser, and the Landis brothers (Abraham and Franklin) all went into business in the 1800s, hungry to put new ideas into motion. In some instances, their designs and products improved existing technology, but in other situations they invented brand new industries. The four businesses they created in Waynesboro were world leaders during their heyday.

George Frick turned novel ideas into a company that became a refrigeration trailblazer. Frick recognized tremendous potential for his cooling apparatus. The machines Frick developed used steam, belt, or direct-connected electric drive. In 1896, an entire train of 16 cars was required to ship Frick’s world’s largest refrigeration unit to Kansas City.

The Industrial Museum archives Frick’s daily company ledgers- massive bound volumes that detail their steady progress from the 1890s to 1950s. The museum also recently received an impressive artifact: a black granite and gold-leaf framed panel of Frick compressor gauges once used by Waynesboro’s Ice and Cold Storage Company. Frick Company is now Johnson Controls, and this firm continues the legacy originally created by Frick’s ingenuity.

Peter Geiser came from humble beginnings, working on his Smithsburg family farm. His father noticed his youthful mechanical aptitude and encouraged Peter’s tinkering. Frustrated with the tedious grain harvesting process (he rode a horse in a constant circle to tramp down the crop), Peter knew there must be an easier method.

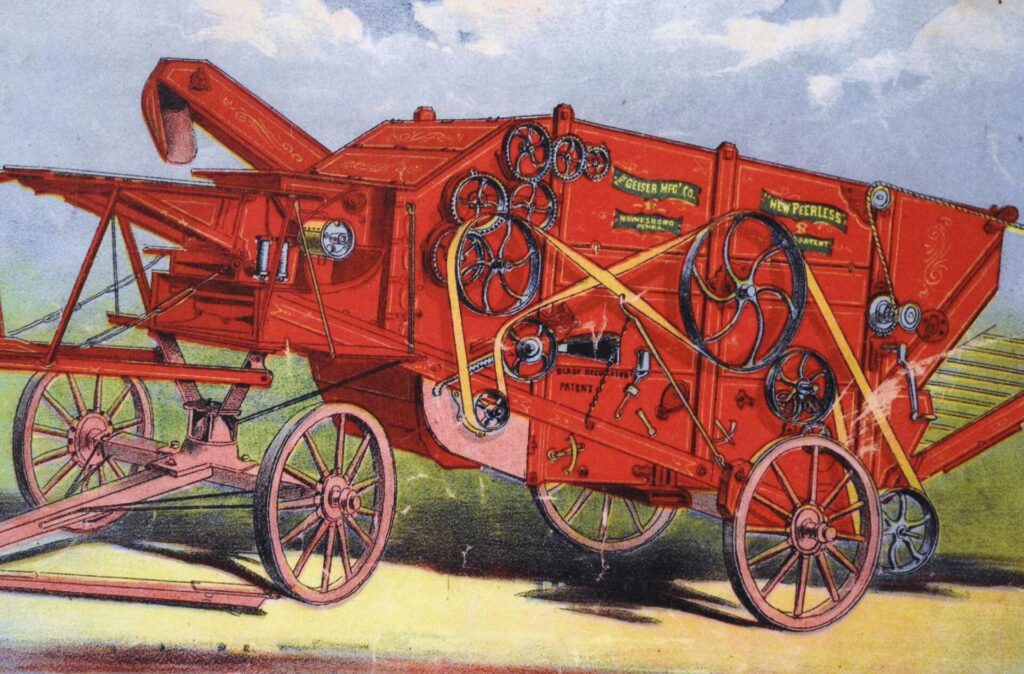

In 1850, Geiser made his first attempt at creating a separator. Two years later, Peter was granted patent number 9341, recognizing the unique features of his machine which served as a thresher, separator, cleaner, and conveyor. That achievement led to the eventual birth of Geiser Manufacturing, which incorporated in 1869. Later, their “Peerless” portable steam engine would be a company best seller.

Geiser’s company prospered, despite a major fire in 1882. A new plant was immediately built, covering an entire city block between Waynesboro’s Broad and Walnut Streets. By 1900, 1000 employees worked in this gigantic facility.

Due to Geiser’s and other local industrial leader’s financial successes, Waynesboro supposedly had more millionaires per capita during this period than anywhere else on earth.

But after Peter Geiser’s death, company fortunes faded after being acquired in 1912 by a larger company. A spectacular late-night blaze- likely the largest fire in Waynesboro history- destroyed Geiser’s vacant plant in August, 1940. Today, the only building that remains is the company’s former office on Second Street.

But Peter Geiser’s substantial success was not forgotten. WAIHT published a book about Geiser’s historic legacy. Authored by Bill Helfrick, Mike Rohrer, and Dave Thompson, the volume is a fascinating account told with well-researched writing and vintage pictures. The book can be purchased at the Industrial Museum.

The Landis brothers came to Waynesboro from Lancaster County, Pennsylvania. Recruited by Peter Geiser, the Landis’s shared some original ideas with Geiser, and helped manage his plant, but eventually, the Landis duo ventured out to create their own companies.

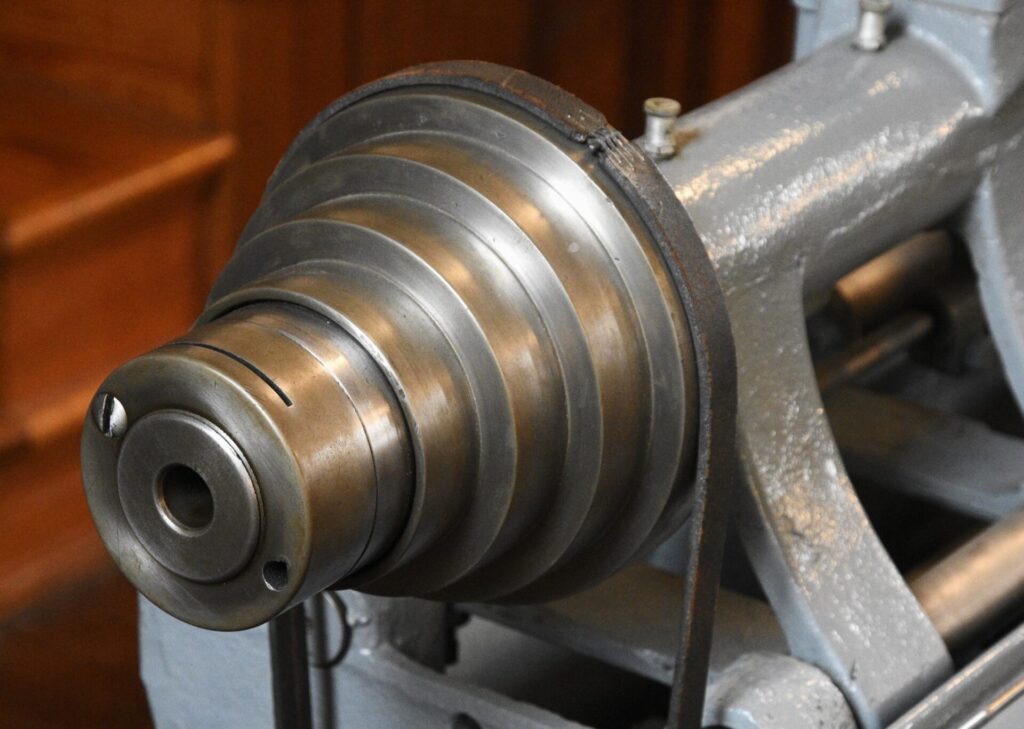

They experimented with various inventions and eventually the Landis’s devised two new marketable products. The first, a bolt cutter, was patented in 1889. The second, a grinding machine, was patented the next year.

At first, a grinder start-up business was deemed more feasible, so Landis Brothers was formed to produce it. After a major fire in 1897 (a recurring industry hazard), the company reorganized as Landis Tool Company. The first grinder shipped under that name sold for $369. Landis’s maiden grinder model would eventually be exhibited in Smithsonian Institution’s Museum of Science and Technology.

In 1903, the Landis brother’s second idea was pursued, a bolt threading machine. The result: Landis Machine Company was born. As these two Landis companies prospered into the 1900s with their revolutionary machines, they sold products worldwide. But constant improvements were required. A staggering 400+ patents were eventually issued to Landis owned companies. Abe and Frank Landis would later be honored for their industry achievements by induction into the American Precision Tool Hall of Fame.

“These four men were talented inventors”, said Brian Shook, President of the Industrial Museum. Shook spent 47 years as an engineer at Landis Machine, and experienced first-hand the evolution of local industry. “Waynesboro was lucky to have them here. They incorporated the whole community into growing their companies”, Shook recalled.

The current Industrial Museum exhibit puts this quartet’s history into perspective with a timeline display. Photographs and documents illustrate how these four major companies evolved; all presented alongside a comparison of world and national events that happened simultaneously.

Also inside the museum, a vintage Landis Machine steam whistle is displayed- a reminiscent artifact mentioned in George Coffman’s 1980 book titled: “The Twenty Minute Whistle”. The once familiar sound of its haunting tone announced it was time to start another work day.

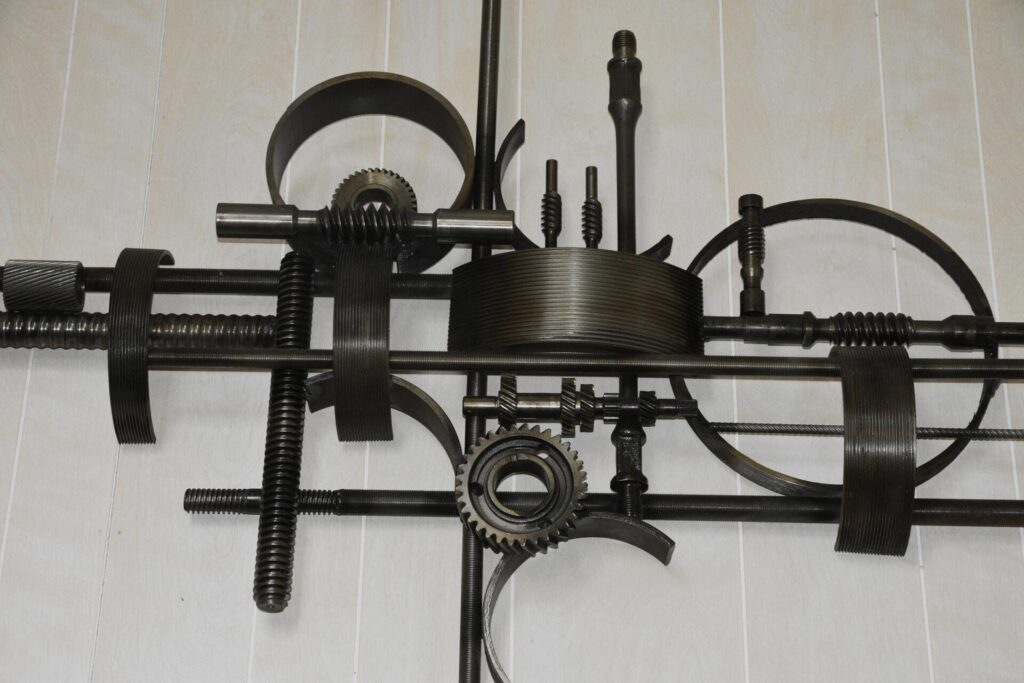

Other historic pieces found here are an early Landis threading machine and original die head. In this museum setting, these polished and precise metal instruments achieve new luster; they are industrial works of art.

A painting of Milton Garland hangs in the Industrial Museum’s entry. Garland’s longevity was legendary. He started working at Frick in 1920, and was credited with 41 patents during his 80-year engineering career. Garland regularly went to his office until 2000, at age 104! His tireless spunk and technical intellect epitomized the spirit that put Waynesboro industry on the world map.

At first look, the charming brick building housing the Industrial Museum is a surprise; it was once the Reformed Mennonite Church; built in 1900. Original wooden pews remain inside, adding a rustic feel. But the church has a direct connection to one of Waynesboro’s industrial titans. Frank Landis designed this structure and donated the land. His good deed was repaid seven decades after his death when in 2000 the church’s fading congregation donated its perpetual use as the Industrial Museum.

The enthusiasm and respect museum members show for Waynesboro’s industrial history is easily recognized. Faces light up when discussing a long-ago invention or little-known company fact. “There’s so much history in this town,” Board Member Rick Mouer said with obvious pride.

Starting in the 1960’s, a series of corporate mergers altered Waynesboro’s industry landscape. “That changed the local flavor”, Brian Shook said. “Multiple generations of Waynesboro families used to work and manage these companies.” But despite loss of some local control through the years, and Landis Tool Company’s eventual move to Maryland, Waynesboro industry still marches forward.

The former Landis Machine, now Landis Solutions, still produces precise threading tools. The Landis Complex, (on the old Landis Tool campus) is run by DL George and Sons, and bustles with industry activity. Beck Manufacturing is a respected maker of pipe nipples and couplings. Shady Grove’s Manitowoc (originally Grove Cranes), is a world-renowned manufacturer of boom, telescoping, and tower cranes.

Waynesboro’s Industrial Museum continues with its acquisitions, programs, and drive for more members. They also hope to foster a new generation of industrial leaders who will be inspired by historic local pioneers.

The museum is located at 235 Philadelphia Avenue in Waynesboro and open Tuesdays from 9am to noon, and by appointment. During an annual summer event, the organization hosts an industry collectibles night, similar to Antiques Roadshow. For more information about other upcoming programs or membership, contact them at 717-762-4460, or visit online: www.waynesboroindustrialtrust.org

*

Embark on a captivating journey through time with our weekly Local History column, where we unravel the forgotten tales and enduring legacies that shaped our communities. Join us in preserving the rich heritage of our hometowns by sharing your stories or suggesting topics for exploration. Together, let us illuminate the past and inspire the future. If you would like to contribute to local history or have a topic you would like covered please reach out to our news department. [email protected]